Worried that your products are being opened or switched? This can ruin your brand's trust. You need a way to show if a package has been tampered with.

Tamper-evident labels are special security stickers that show irreversible proof if someone tries to remove them. They work by leaving behind a pattern, like the word "VOID," or by self-destructing, making it impossible to reapply the label without showing clear evidence of tampering.

It’s a simple concept, but the technology behind it is quite impressive. I’ve spent years working with clients to protect their assets, and these labels are often the first line of defense. They act as a strong deterrent and a clear communication tool. If the seal is broken, you know it instantly. This guide will walk you through how these labels work and which type might be right for you. Let's dive into the details to see how they can secure your products.

How Do Film-Based VOID Labels Work?

Concerned about someone opening a sealed container without you knowing? This can lead to warranty fraud or contaminated products. You need a clear, instant sign of tampering.

VOID labels1 provide this sign. When peeled, they leave a permanent "VOID" message on the surface. This shows that the seal has been compromised. The label itself is also damaged, so it cannot be put back on.

I often explain to my clients that the real genius of these labels is in their layered construction2. It’s not just a simple sticker. It’s a multi-part system designed to fail in a very specific, visible way. This deliberate failure is what gives you security. Think of it as a lock that breaks to show it's been forced.

The Hidden Message Mechanism

The label is made of several layers. There's a top film, a special release coating, and a strong adhesive. The word "VOID" (or a custom message) is created within these layers. When someone tries to peel the label, the adhesive sticks to the product surface more strongly than parts of the release coating. This causes a precise separation, leaving the security message behind.

Types of VOID Residue

There isn't just one type of VOID label. We can tailor the effect based on the product and the level of security needed.

| Residue Type | How It Works | Best For |

|---|---|---|

| Total Transfer | The entire adhesive layer, with the VOID pattern, transfers to the surface. The label itself becomes transparent. | Securing non-reusable packaging like evidence bags or shipping boxes. |

| Partial Transfer | Part of the adhesive transfers to the surface, and part stays on the label. Both show the VOID pattern. | Electronics, machine panels, and asset tracking. |

| No Residue | The VOID pattern appears on the label itself when peeled, but leaves no sticky residue on the surface. | Reusable containers, aircraft doors, or rental equipment. |

This choice is important. For a client in logistics, we used total transfer labels on their high-value shipments. They needed undeniable proof of tampering for insurance claims. For another client who rents medical equipment, we used no-residue labels to avoid damaging the expensive machines.

Are Honeycomb Pattern Labels a Good Alternative?

Do you need a tamper-evident solution that looks different from the standard "VOID" text? Sometimes, a unique pattern provides a better visual cue or fits your branding better.

Honeycomb pattern labels work just like VOID labels1. When someone tries to remove them, they leave behind a distinct honeycomb-shaped residue. This pattern is immediately recognizable as a sign of tampering and is very difficult to clean off or replicate.

In my experience, the choice between VOID and honeycomb often comes down to aesthetics and industry norms. Some industries, like pharmaceuticals, prefer the clear, instructional text of "VOID OPEN." Others, in consumer electronics, might choose the more geometric and modern look of a honeycomb pattern. The security level is comparable. Both rely on the same principle of delamination to reveal a hidden pattern. The key is that the evidence left behind is obvious and cannot be reversed.

How the Honeycomb Pattern is Formed

The technology is very similar to VOID labels1. The label substrate, usually a PET film, has a special coating applied in a honeycomb pattern.

- Layered Structure: The label consists of a top surface, the patterned release layer, and the adhesive.

- Adhesive Bond: The adhesive is engineered to have a very high tack, meaning it sticks very strongly to the product surface.

- Pattern Separation: When peeled, the adhesive bond is stronger than the release layer in the shape of the honeycomb. This forces the label to separate, leaving parts of the metallic or colored layer on the product in that specific pattern.

Comparing Honeycomb to Standard VOID

Both are excellent choices, but they have subtle differences that might matter for your application.

| Feature | Honeycomb Pattern | VOID Text |

|---|---|---|

| Visual Cue | Geometric, language-neutral pattern. | Clear, instructional English text. |

| Customization | The pattern size can be adjusted. | The text can be customized (e.g., "SEAL BROKEN"). |

| Industry Use | Popular in electronics, retail packaging, and logistics. | Common in government, evidence handling, and warranty seals. |

| Deterrence | High. The pattern is complex and signals high security. | High. The message is a direct warning. |

A few years ago, we worked with a cosmetics company. They felt the word "VOID" was too aggressive for their brand image. We designed a custom, small-scale honeycomb pattern label for them. It provided the security they needed while matching their elegant packaging.

Can Simple Paper Labels Also Be Tamper-Evident?

Are you looking for a more cost-effective tamper-evident solution? Maybe you don't need high-security film labels, but you still want to prevent easy removal of your seals.

Yes, paper labels can be made tamper-evident. They use a method called "kiss-cutting3" or "destructible material." Instead of leaving a residue, these labels are designed to break into tiny pieces if someone tries to peel them off, making removal impossible in one piece.

This is a great option for situations where the main goal is to prevent a clean transfer of a label from one product to another. I often recommend this for things like food packaging seals or price tags on retail items. The label's destruction provides clear evidence of tampering, even if it doesn't leave a "VOID" message. It’s a different approach to the same problem: creating irreversible evidence.

The Science of Destructible Labels

There are two main ways we make paper labels tamper-evident. Both rely on making the label material fragile.

Ultra-Destructible Vinyl

This isn't paper, but it behaves in a similar way and is a very popular choice.

- Material: We use a special cast vinyl material that is very brittle.

- Adhesive: It's paired with a very strong, aggressive adhesive.

- How it Works: Once the label is applied and the adhesive cures (usually after 24 hours), the bond to the surface is stronger than the vinyl itself. If you try to remove it, the vinyl shatters into tiny, eggshell-like pieces. It's incredibly frustrating to remove, which is exactly the point.

Kiss-Cut Paper Labels

This method uses standard paper but adds a mechanical weakness.

- Process: We use a die-cutting machine to make a series of very fine cuts across the surface of the label. These cuts go through the paper but not the backing liner (hence the name "kiss-cut").

- Pattern: The cuts can be in a simple crosshatch pattern or a more complex design.

- How it Works: The cuts create fracture points. When someone tries to peel the label, it tears along these pre-cut lines, preventing it from being removed in one piece.

We helped a local bakery that was having problems with people swapping labels on their pastry boxes. Ultra-destructible vinyl was too expensive for them. We created a simple paper label with a fine kiss-cut pattern. It worked perfectly and was well within their budget.

What Materials Are Best for Tamper-Evident Labels?

Are you wondering which material will hold up best for your specific product and environment? The choice of material is critical for the label's performance and security.

The best material depends on the application. For high-security needs, metallized PET (polyester) film is the industry standard. It's durable and perfect for creating VOID or honeycomb effects. For a budget-friendly option where destruction is key, destructible vinyl or kiss-cut paper works well.

Choosing the right material is a conversation I have with every client. It’s about balancing security, durability, cost, and the surface it’s being applied to. A label for a cardboard box that ships across the ocean has very different needs than a warranty seal inside a computer. We need to consider temperature, moisture, and potential chemical exposure. The goal is to ensure the label works as intended when it matters most.

A Breakdown of Common Materials

Let's look at the pros and cons of the most common materials we use in our production process. Understanding these trade-offs will help you make a more informed decision.

| Material | Key Features | Common Applications |

|---|---|---|

| PET (Polyester) Film | - Very durable, strong, and stable.- Resistant to heat, chemicals, and UV.- Ideal for creating VOID/patterned residue. | Electronics, government documents, pharmaceuticals, asset tags. |

| Ultra-Destructible Vinyl | - Extremely brittle, shatters upon removal.- Conforms well to curved surfaces.- Paired with a very strong adhesive. | Warranty seals, calibration labels, sealing access panels. |

| Paper | - Low cost.- Can be made tamper-evident with kiss-cuts.- Not water-resistant unless coated. | Food packaging, retail price tags, promotional seals. |

| Acetate | - Highly destructible, but can be removed with solvents.- Often used for one-time seals. | Sealing envelopes, software boxes, and temporary seals. |

The Role of Adhesives

The material is only half the story. The adhesive is just as important. We use different types of adhesives depending on the surface the label will stick to.

- Standard Permanent: Good for smooth surfaces like metal, glass, and high-energy plastics.

- High-Tack Permanent: Designed for rough or textured surfaces, like some plastics and powder-coated metal.

- Removable: This is not used for security labels, as it defeats the purpose.

I remember a case where a client's labels were failing in a hot warehouse. They were using a standard adhesive that softened in the heat. We switched them to a PET label with a high-temperature acrylic adhesive, and the problem was solved. The material and adhesive must work together.

How Can You Customize a Tamper-Evident Design?

Do you need more than a generic "VOID" label? Customization can enhance security and integrate the label with your branding, making it a powerful part of your product.

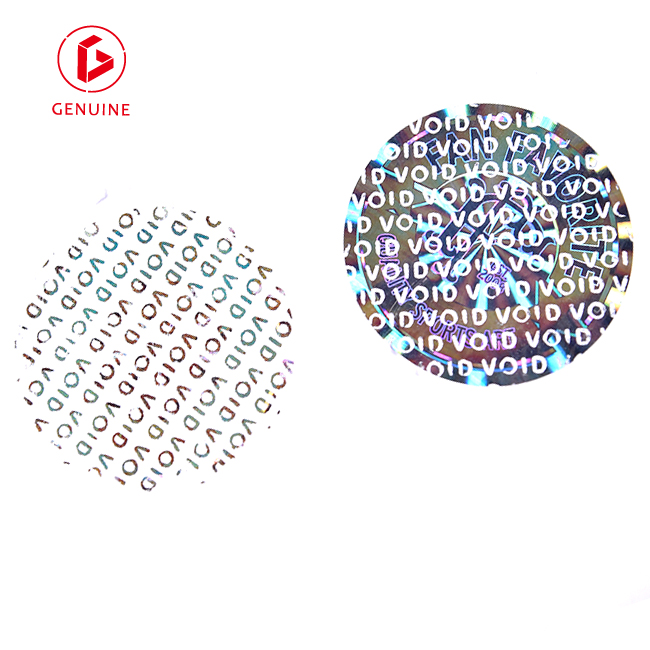

You can customize almost every aspect of a tamper-evident label. We can change the hidden message from "VOID" to your company name, print your logo on the surface, add serial numbers, or use unique holographic patterns4 for even higher security.

Customization is where we can really add value for our clients. A custom design is much harder for a counterfeiter to copy than a standard, off-the-shelf label. It makes your security seal unique to you. I always encourage clients to think about this. Adding a simple logo or a specific word in the VOID pattern transforms the label from a generic security product into a branded security feature. This builds customer trust and makes your product look more professional.

Levels of Customization

We can think of customization in several layers, from simple visual changes to complex, high-security features.

Level 1: Surface Printing & Basic Changes

This is the most common type of customization.

- Logo and Text: We can print your company logo, contact information, or other text on the top layer of the label in full color.

- Serial Numbers & Barcodes: Each label can have a unique serial number or barcode for tracking and authentication. This is essential for asset management and warranty claims.

- Custom VOID Message: Instead of the standard "VOID," the hidden message can be your company name, a logo, or a specific symbol.

Level 2: Advanced Security Features

For higher-risk applications, we can integrate more advanced features.

| Feature | Description | Security Benefit |

|---|---|---|

| Holographic Patterns | A custom hologram is embedded into the label. | Extremely difficult to replicate, provides instant visual authentication. |

| UV Invisible Ink | A logo or code is printed that is only visible under UV light. | Adds a covert layer of security that a counterfeiter might miss. |

| Color-Shifting Ink | The printed ink changes color when viewed from different angles. | A high-tech feature used on currency; very hard to copy. |

| Microtext | Tiny text that is unreadable to the naked eye. | Another covert feature that is hard to reproduce accurately. |

I worked with a government agency that needed to seal sensitive election equipment. We created a label for them that had a custom VOID message with their official seal, a unique serial number for each unit, and a hidden UV feature. This multi-layered approach gave them complete confidence that their equipment was secure.

Conclusion

Tamper-evident labels are a critical tool for protecting products, assets, and brand integrity. They provide clear, irreversible proof of unauthorized access, offering peace of mind to you and your customers.

VOID labels offer a clear indication of tampering, ensuring your products remain secure and trustworthy. ↩

Layered construction in labels ensures they fail visibly when tampered with, enhancing security. ↩

Kiss-cutting creates fracture points in labels, preventing clean removal and ensuring tamper evidence. ↩

Holographic patterns add a high-security feature to labels, making them difficult to replicate. ↩