Are your paper certificates at risk of being faked or altered? This can damage your reputation and create serious security breaches. It's a constant worry for many organizations.

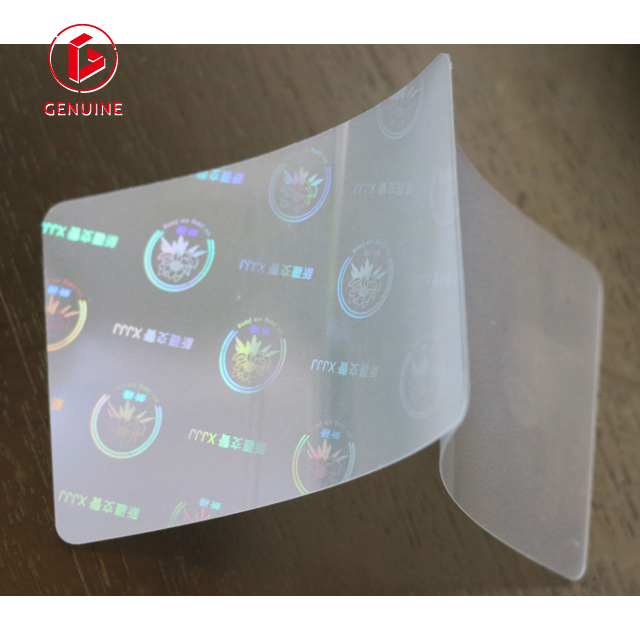

A heat laminate pouch secures documents by sealing them in a protective layer that is tamper-evident. More importantly, we can embed advanced anti-counterfeit features like holograms, special inks, and microtext directly into the laminate, making unauthorized duplication nearly impossible to achieve.

Adding a layer of plastic to a document is a good start, but it's not enough to stop determined counterfeiters. The real security comes from the technology we embed within that plastic layer. It transforms a simple pouch into a powerful security device. But how do these specific features actually work to stop fakes? Let's explore the details of how we build these layers of protection, starting with the most visible feature.

What Makes a Holographic Laminate Pouch So Hard to Fake?

You see a certificate and worry that anyone with a good printer could copy it. This common problem undermines the trust in your documents and your entire organization's credibility.

A holographic laminate pouch is difficult to fake because the hologram itself is made with specialized laser technology. These complex, multi-layered images cannot be scanned or photocopied accurately. This provides an immediate and easy-to-verify security feature that stops most counterfeit attempts dead in their tracks.

The magic of a hologram is in its complexity. It’s not just a shiny sticker. When we design a hologram, we are creating a microscopic structure that manipulates light. This is why you see different images or colors when you tilt the document. A simple scanner or camera can't capture this three-dimensional, light-reactive information. I remember working with an election commission that needed to secure voter ID cards. We created a custom dot-matrix hologram with their national emblem. When tilted, the emblem appeared to rotate. This simple visual check allowed poll workers to instantly verify a real card without any special equipment. It's a perfect example of high-tech security made simple for everyday use.

Deeper Dive: Holographic Technology Explained

To truly understand its power, we need to look at the different types of holograms we can use. Each offers a unique layer of security.

- 2D/3D Holograms: These create a sense of depth, making a flat image appear three-dimensional. It's a classic effect that is still very effective.

- Dot-Matrix Holograms: These are created with countless tiny dots, allowing for complex and kinetic effects like sparkling, flowing, or animated images.

- Flip-Flop Images: This technique allows two or more distinct images to occupy the same space on the hologram. Tilting the document switches between the images.

Here is a simple table to show the difference:

| Feature | Standard Laminate | Holographic Laminate |

|---|---|---|

| Visual Security | None | High (Easy to verify) |

| Copy Protection | Low (Easily photocopied) | Very High (Cannot be scanned) |

| Customization | Low (Only size/thickness) | High (Custom logo, text, effects) |

| Perceived Value | Low | High |

By combining these techniques, we can build a hologram that is completely unique to your organization.

Can You Add Invisible Security Features to a Laminate Overlay?

Visible security is great, but what about a second line of defense? Sophisticated counterfeiters might try to replicate visible features, leaving you vulnerable if that's all you rely on.

Yes, you can absolutely add invisible security features. We frequently use UV fluorescent printing on our laminate overlays. This ink is completely invisible to the naked eye but glows brightly under an ultraviolet (UV) light, revealing a hidden logo, text, or pattern.

Think of UV ink as a secret message for authorized verifiers. It's a simple but incredibly effective tool. Since the ink is invisible in normal light, a counterfeiter might not even know it's there. They might produce a visually convincing fake, but it will fail the verification process as soon as a UV light is shined on it. We often recommend this for government permits and academic transcripts. For one university client, we printed their crest in invisible UV ink on the laminate for their diplomas. It gave them a quick and foolproof way to distinguish real diplomas from fakes during background checks, without cluttering the visible design of the document.

Deeper Dive: Covert and Forensic Security

Invisible features fall into a category called "covert security." These are features not immediately obvious to the public but easily checked by someone with the right tool. UV printing is the most common, but we can go even deeper.

- Microtext: This involves printing extremely small text that looks like a simple line to the naked eye. You need a magnifying glass to read it. We can embed your organization's name or a secret code within the lines of a certificate's border. A photocopier can't resolve this tiny text; it will just blur into a solid line, making a forgery easy to spot.

- Security Threads: Similar to what you see in banknotes, we can embed a thin thread into the laminate itself. This thread can have its own properties, such as being holographic or printed with microtext.

- Chemical Reaction Coatings: For the highest level of security, the paper document itself, before lamination, can be treated. These coatings react to tampering agents like bleach or solvents, leaving a permanent stain and proving the document has been altered.

These features work together to create a multi-layered defense system.

| Security Level | Feature | How to Verify |

|---|---|---|

| Level 1 (Overt) | Hologram | Tilt the document in light |

| Level 2 (Covert) | UV Invisible Ink | Use a UV blacklight |

| Level 2 (Covert) | Microtext | Use a magnifying glass |

| Level 3 (Forensic) | Chemical Coatings | Attempted chemical alteration |

This layered approach ensures that even if one feature is compromised, others are still in place to protect the document's integrity.

How Do Serial Numbers and OVI Ink Boost Laminate Security?

Static security features are strong, but what if you need to track each individual document? A generic hologram protects the design, but it doesn't make each certificate unique and traceable.

Serial numbers make each laminate pouch unique, allowing for tracking and verification in a database. OVI (Optical Variable Ink) adds another dynamic visual feature. This special ink changes color when viewed from different angles, a feature that is extremely difficult and expensive to replicate.

Combining these two elements provides a powerful one-two punch for security. First, the serial number gives each document a unique identity. We can print this using laser engraving or specialized ink, making it a permanent part of the pouch. This is crucial for things like tax stamps or product authentication labels. I’ve seen this work wonders for a government client managing alcohol tax revenue. Each bottle's tax stamp had a unique QR code and serial number. This allowed inspectors to scan a bottle in the field and instantly verify its legitimacy in a central database. Second, OVI ink provides another quick visual check. Seeing the ink shift from green to blue, for example, is a clear sign of authenticity, just like on many high-value banknotes.

Deeper Dive: Variable Data and Advanced Inks

The key concept here is moving from static to dynamic security. Every document becomes a unique, trackable item.

Variable Data Printing (VDP)

This is the technology we use to print unique information on each and every laminate. It's not just for serial numbers. We can use it for:

- Sequential Numbering: The most basic form, like 0001, 0002, 0003.

- Barcodes & QR Codes: These can hold much more information, like a website link for verification, a batch number, or production date. A QR code can link directly to a secure online portal to confirm the document's status.

- Personalized Information: For ID cards, we can print the holder's name or ID number directly onto the security laminate.

The Science of OVI Ink

OVI ink is not like normal ink. Its color-shifting properties come from tiny metallic flakes suspended in the ink. These flakes reflect light differently at different angles.

| Feature | Standard Ink | OVI Ink |

|---|---|---|

| Appearance | Static, single color | Dynamic, shifts between 2+ colors |

| Replication | Easy (with a good printer) | Extremely difficult and expensive |

| Verification | None | Simple tilt of the document |

| Common Use | General printing | Banknotes, high-security documents |

By printing a serial number with standard ink and placing a patch of OVI ink next to it, you create a document that is both uniquely identifiable and visually secure against casual and professional counterfeiters.

How Do We Customize a Laminate Pouch for Maximum Security?

You see all these features, but how do they come together? An off-the-shelf solution might not fit your specific needs or provide the level of security your brand or agency requires.

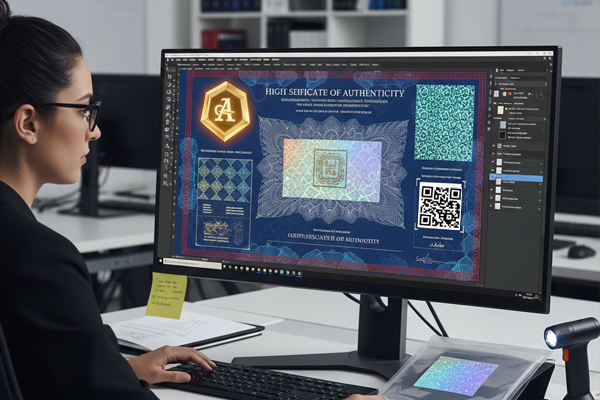

We customize a laminate pouch through a one-stop process. It starts with understanding your specific security risks, then moves to design, feature selection, production, and quality control. Every step is tailored to create a unique solution just for you.

The customization process is where our 15+ years of experience really shines. We don't just sell you a product; we build a security solution with you. I always start by asking clients: "What are you trying to protect, and who are you trying to stop?" The answer determines everything. Protecting a university diploma from small-scale fakes is different from securing a national tax stamp against organized crime. Once we understand the threat, we design a unique combination of features. We might suggest a custom hologram of your logo, combined with microtext of your company motto and a QR code for online verification. This holistic approach ensures there are no weak points.

Deeper Dive: Our One-Stop Customization Workflow

Our process is designed to be thorough and collaborative. We guide you through each stage to ensure the final product meets your exact specifications and provides robust, long-term security.

- Consultation & Risk Assessment: We begin with a deep conversation. We discuss the document's purpose, its value, potential threats, and how it will be verified in the field. This is the most critical step.

- Security Design & Layout: Based on the assessment, our design team creates a digital mockup. This is where we propose a specific combination of features.

- Hologram Concept: We'll design a custom hologram incorporating your branding.

- Covert Feature Placement: We'll strategically place UV ink and microtext.

- Variable Data Integration: We'll decide on the format for serial numbers or QR codes.

- Sample Production & Approval: We produce a physical sample for you to review. You can hold it, test the features, and ensure it meets your expectations before we begin mass production.

- Mass Production & Quality Control: Our production line operates under strict security protocols. Every sheet is inspected to ensure consistent quality and that all security features are perfectly executed.

- Secure Delivery: We manage the international shipping and logistics to ensure your secure laminates arrive safely and on time.

This structured process, from initial idea to final delivery, guarantees a solution that is not only secure but also perfectly aligned with your operational needs.

Conclusion

In short, a custom heat laminate pouch with layered security features like holograms, UV ink, and serial numbers is the best way to protect your vital paper documents.